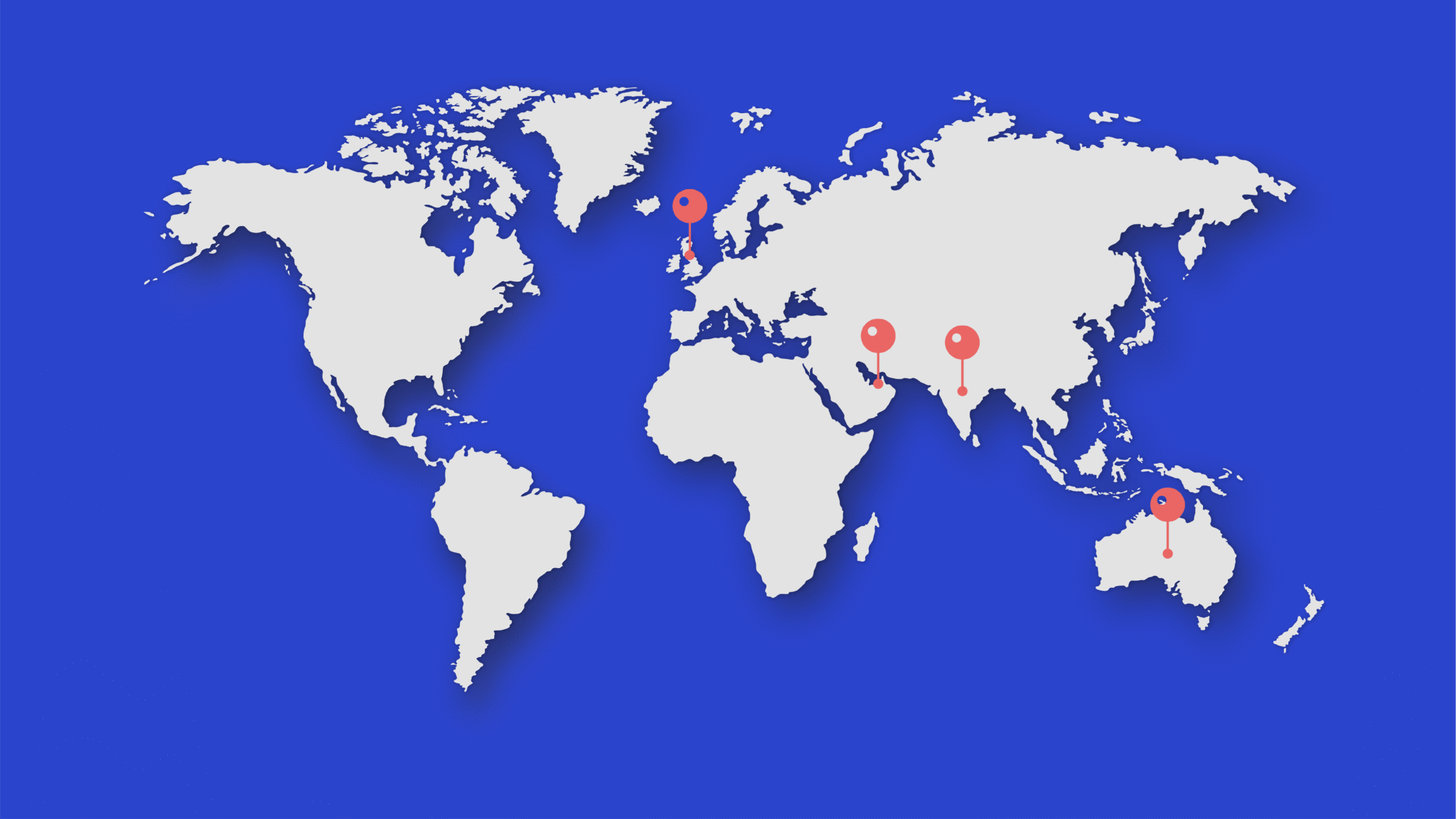

Founded in 1967, Metaval has grown from a small family business into a global leader in industrial engineering, with cutting-edge facilities in Australia, India, and the UAE. We specialize in precision-engineered valves, instrumentation, and flow measurement systems, offering comprehensive solutions through our in-house forging and casting capabilities. Our unwavering commitment to quality and innovation has earned us a reputation as a trusted partner in industries worldwide.

To deliver innovative, high-quality engineering solutions that empower industries worldwide, ensuring

reliability, precision, and excellence in every product we create.

To be the global leader in industrial engineering, transforming ideas into essential components that

drive progress and shape the future of industries across the world.

We are driven by innovation, quality, and integrity, ensuring every product meets the highest standards.

Our focus on customer satisfaction, sustainability, and collaboration guides us in delivering

reliable solutions and fostering trust with our clients and partners

To deliver innovative, high-quality engineering solutions that empower industries worldwide, ensuring reliability, precision, and excellence in every product we create.

To be the global leader in industrial engineering, transforming ideas into essential components that drive progress and shape the future of industries across the world.

We are driven by innovation, quality, and integrity, ensuring every product meets the highest standards. Our focus on customer satisfaction, sustainability, and collaboration guides us in delivering reliable solutions and fostering trust with our clients and partners

Ansh, the 28-year-old director of Metaval, is a young, dynamic, and skilled leader with a passion for innovation. He graduated from Monash University in Australia with a degree in business administration. He is leading a team of over 200 employees and overseeing the company's digital transformation.

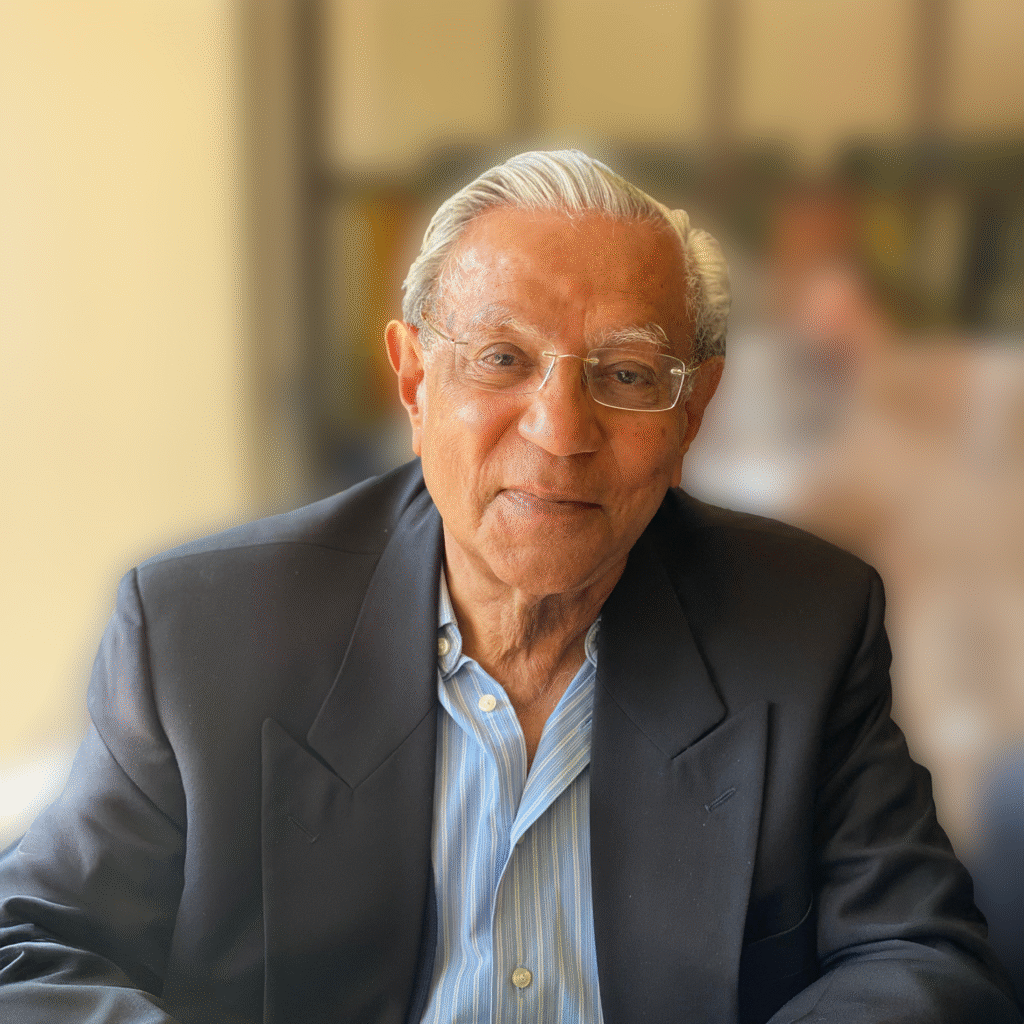

Micro Precision Pvt. Ltd. was founded by Mr. K.P. Chandhok, becoming the first manufacturer of primary flow elements in India. With a vision to fuel India’s industrial growth, we transformed raw materials into precision flow components, sparking a legacy that now spans over 40 countries.

Pioneered the launch of the Multi-Hole Orifice Plate in India, setting new benchmarks in flow measurement.

Introduced the Multi-Stage Orifice Plate, reinforcing our leadership in flow element technology.

Recognized as India’s most prominent and trusted manufacturer of primary flow elements.

Became a key supplier to industry giants including Emerson, Yokogawa, Endress+Hauser, Reliance, EIL, and BHEL.

Commissioned an in-house Flow Calibration Unit to strengthen product accuracy and reliability.

Micro Precision was acquired by WIKA, marking a pivotal advancement in our journey.

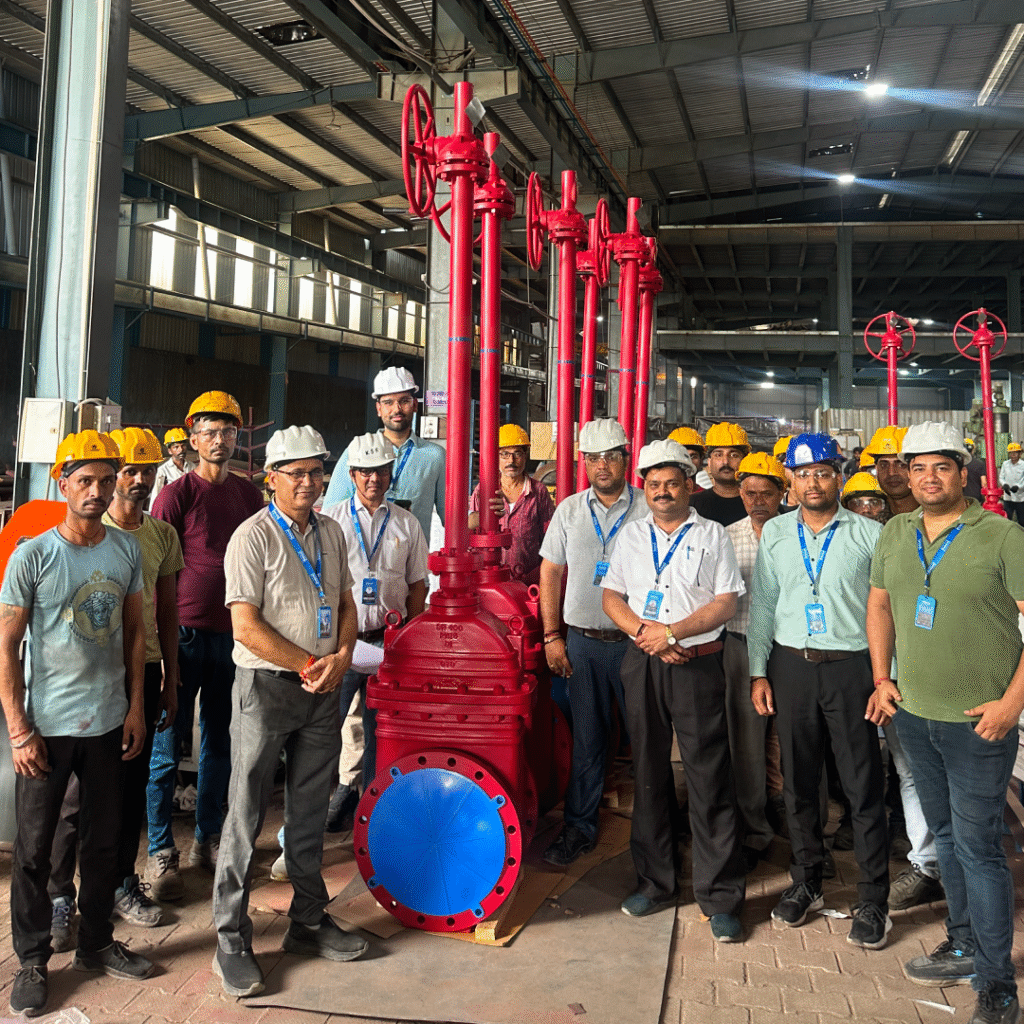

Established in Faridabad by Mr. Atul Chandhok and Mr. Ansh Chandhok , a manufacturing powerhouse offering valves, flow elements, forged and instrumentation products, all under one roof.

Launched the nation’s largest fully automated gravimetric flow calibration unit — driving new standards in precision.

Led by CEO Ansh Chandhok and Chairman Mr. Atul Chandhok, we acquired Metaval Australia — a legacy valve manufacturer since 1967 and a distributor of leading instrumentation brands across Oceania.

In the same year, we rebranded JAV Forgings to Metaval, establishing our global identity as a fully integrated engineering company.

Opened our Dubai sales office (Metaval FZCO) to serve the Middle East market with faster, localized support.

Established our Abu Dhabi office to serve the oil & gas, water, chemicals, and infrastructure sectors with regional agility and technical expertise.

UK Sales Office – Europe Unlocked

Our UK sales office now enables faster turnaround times, dedicated customer support, and streamlined access to our products across the European region

Casting Division Launched: Daily capacity of 25,000 kg, crucibles from 50 kg to 5000 kg delivering unmatched scale and flexibility in support of our valves business.

Forging Division Expanded: New die-forging hammer and 1000-ton capacity enhancement.

Fully Integrated Operations: From forging and casting to machining, welding, and testing — complete in-house control ensures top-tier quality, innovation, and delivery.

ADNOC Approved: Achieved ADNOC approval for flanges, a key milestone in our commitment to global standards.

Under the leadership of CEO Ansh Chandhok, Metaval is scaling new heights. With a strong foundation in engineering excellence and a future-focused mindset, we’re redefining industrial solutions — combining technology, sustainability, and global responsiveness.

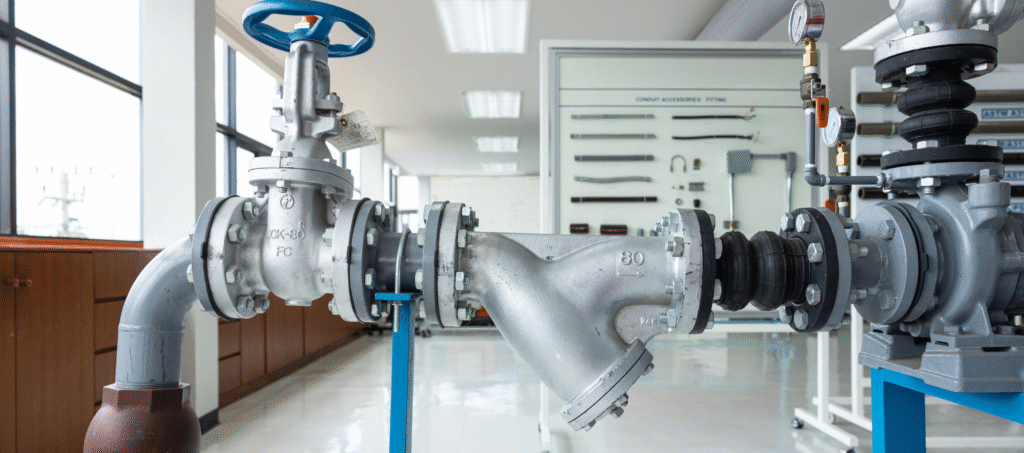

Metaval Australia is a leading Australian company that provides engineered products to major industries across the country. Established in 1967, the company initially served the paper industry but has since expanded its product range to include all types of valves and actuators, piping products, flow measurement, instrumentation, temperature, level, water technology, flame arresters, mixers, strainers, heat exchangers, steam heaters, direct in line pumping, bin aeration, and proximity sensors. Representing leading global companies in their respective fields, Metaval has a strong installed base across various industries such as agribusiness, water and wastewater, cement and quarry, chemical, food and beverage, defence utilities, mining, oil and gas, paint and coatings, process refining, food & beverage and pulp and paper.

Metaval India has been a trusted provider of industrial engineering supplies since 1967. We specialize in in-house design, manufacturing, fabrication, and testing, ensuring the highest quality and efficiency in every project. Our comprehensive capabilities span across five main divisions: valves, flow measurement, instrumentation, skids and forgings. Having these divisions under one roof allows us to maintain control over our supply chain, offer competitive pricing, and deliver products with exceptional speed. With state-of-the-art manufacturing facilities strategically located in Australia, India, and Dubai with offices in the UK and Abu Dhabi. Our global presence ensures we can meet the needs of clients worldwide. Our team of highly trained industry specialists, with over 55 years of experience, is dedicated to providing top-quality products and innovative solutions.

Metaval’s Dubai and Abu Dhabi sales offices serve as key hubs for our operations in the Middle East, providing local expertise and support to our regional clients. These offices are integral to expanding our global reach, allowing us to deliver our high-quality engineering solutions and products more effectively across the region. With a focus on customer service and tailored solutions, our Dubai and Abu Dhabi teams ensure that Metaval’s commitment to excellence is upheld in every interaction.

Metaval Industries Private Limited, a newly established casting foundry in Faridabad, plays a crucial role in the supply chain of Metaval Engineering and its affiliated companies. By providing high-quality, precision castings, the foundry ensures a reliable and consistent supply of essential components. This in-house capability allows Metaval to maintain stringent quality control, reduce lead times, and enhance the overall efficiency of its operations, ensuring that all affiliated companies benefit from a streamlined and dependable supply chain.

Micro Precision Product Private Limited based in Faridabad are key affiliates of Metaval, specializing in testing and calibration services. These companies provide precise and reliable calibration for all of Metaval’s in-house products as well as for external products. Their expertise ensures that all products meet the highest standards of accuracy and performance, supporting Metaval’s commitment to quality and reliability across all operations.

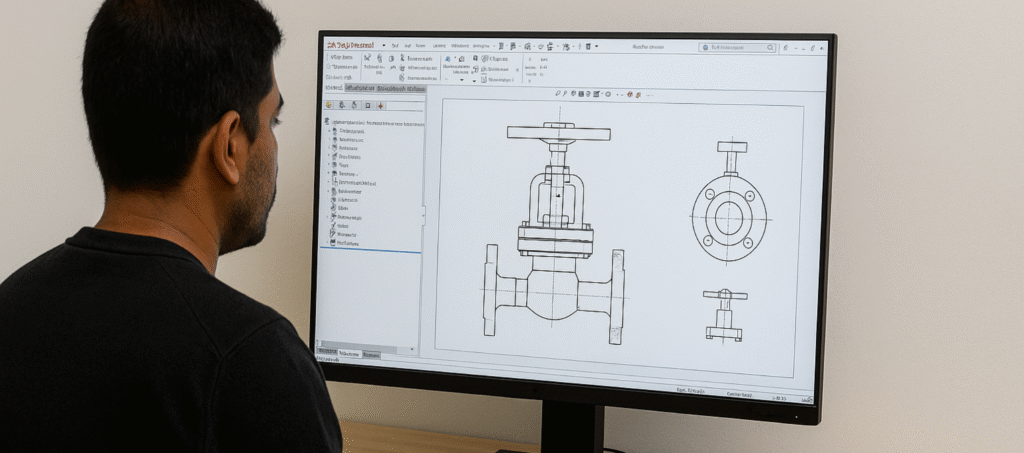

A dynamic and experienced team of professionals to recommend the best solution according to the customer’s requirement.

Softwares:

SolidWorks for simulation

AutoCAD for 2D

Forging unit

(Max 5MT. Single piece and/or 2200mm

diameter)

Sand casting: Production capacity ranging from 1 kg to 1800 kg per piece in ferrous and non-ferrous alloys, supported by an in-house heat treatment facility.

Casting simulation tools: Ensuring precise design of patterns, cores, Ingates, runners, and risers for optimal performance.

Pattern shop:

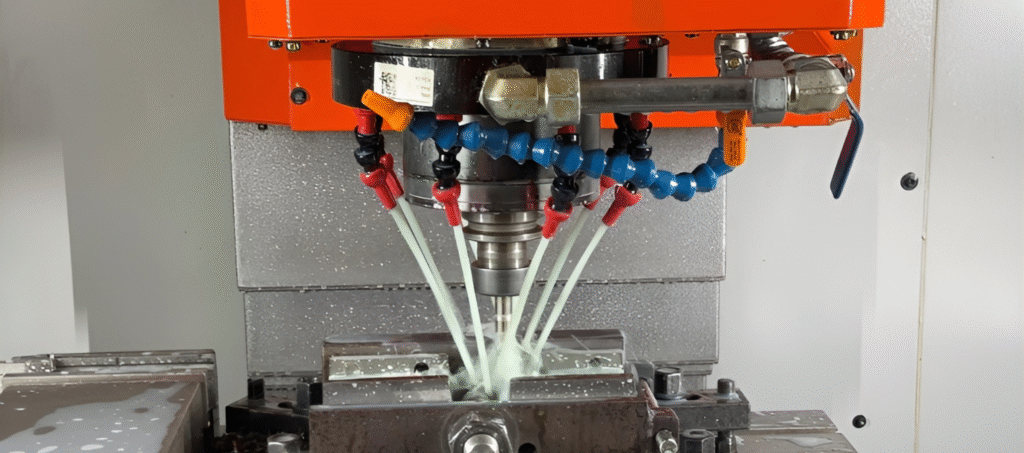

Equipped with conventional and CNC/VMC machines to create flawless patterns and cores.

We offer advanced heat treatment processes.

Annealing

Normalizing

Tempering

Hardening

Quenching

Solution Treatment

Stress Relieving

Equipped with:

Band Saw

Overhead Crane

Plasma Cutting Machines

Vertical Turning Centre

Heavy Duty Lathe

CNC Multi-Spindle Drilling Machines

Drilling Machines

Grinding Machines

CNC Machines

Milling Machines

Plannar

VMC Machines

Forging Hammers

Forging Furnaces

Heat Treatment Furnaces

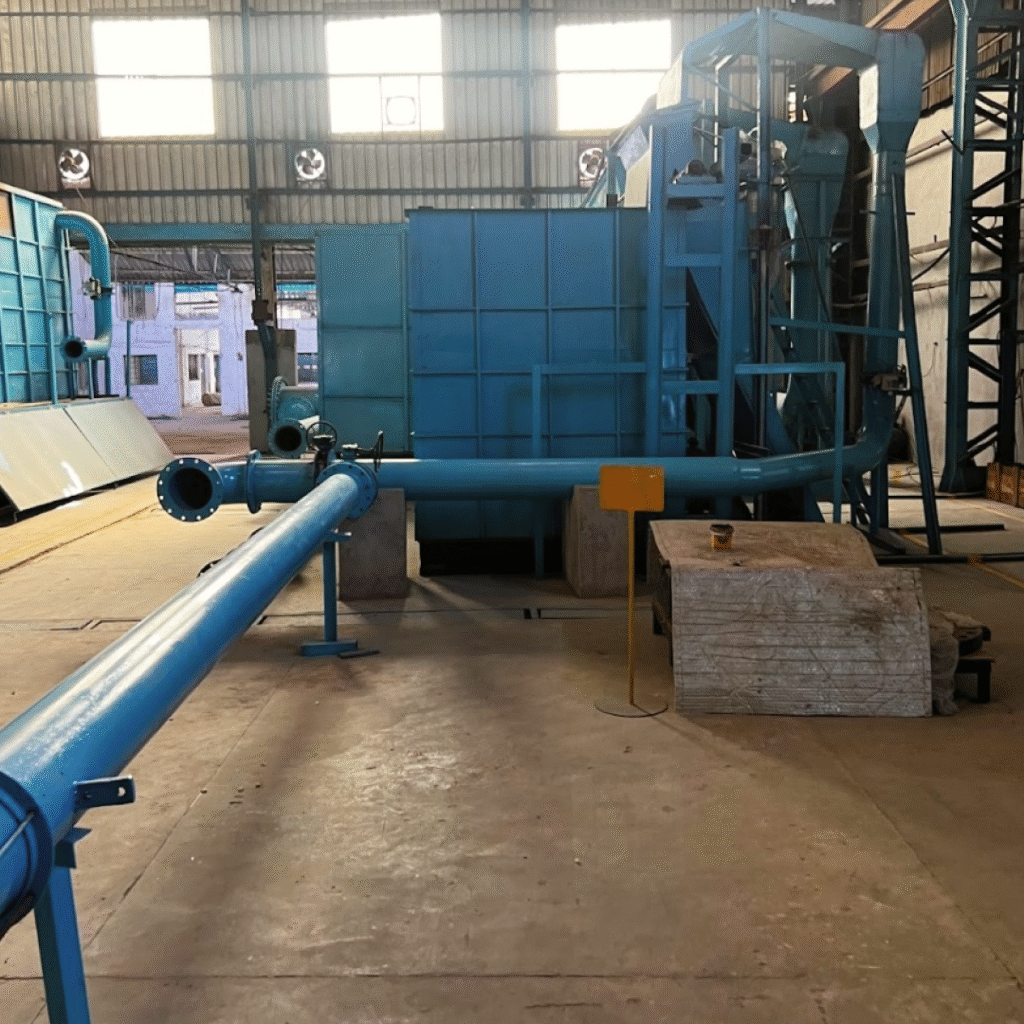

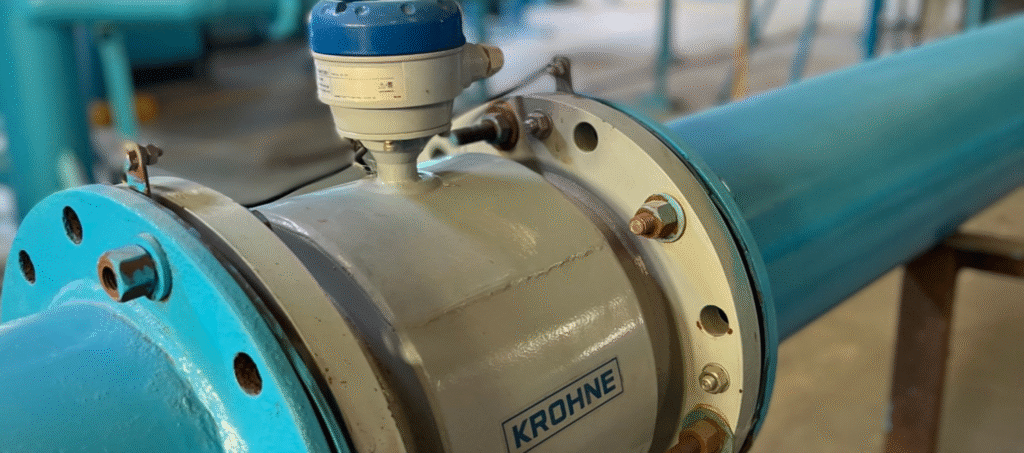

India’s Largest Gravimetric Wet Flow Lab!

FLOW LAB is NABL approved, ISO 17025 :

2017 Compliant, ISO 4185: 1980 / COR 1: 1993 Compliant

Fully automated through the SCADA system

India’s largest weight tank:

40,000 Kgs. Size Range: ¼” to 60” Ability to calibrate on 4 rigs

simultaneously

Products We Service:

Primary Flow Meters, Electromagnetic, Turbine, Ultrasonic, Vortex, Coriolis, Mass, Valves

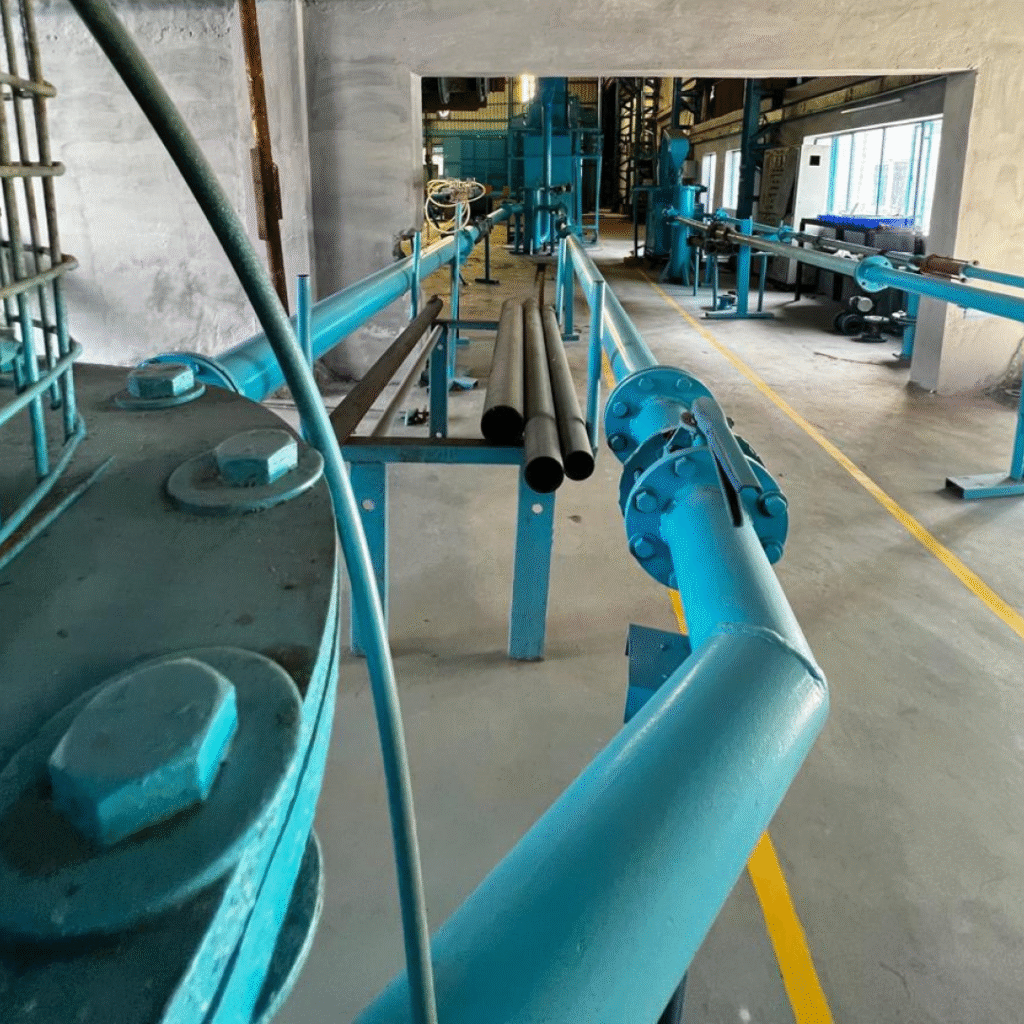

RIG 1

Flow range:

0 to 30 m3/hr

Load Cell Capacity: 400 Kgs

RIG 2

Flow range:

10 to 200 m3/hr

Load Cell capacity: 2000 Kgs

RIG 3

Flow range:

50 to 1100 m3/hr

Load Cell capacity: 11000 Kgs

RIG 4

Flow range:

500 to 3200 m3/hr

Load Cell capacity: 40000 Kgs

RIG 5

Flow range:

0.8 m3/h to 30 m3/h

Load Cell capacity: 11000 Kgs

Fabrication of large-size venturi tubes, flow nozzles, V-cone, Strainers. Large open area and adequate lifting facility i,e, EOT Crane available to handle material. Qualified welders available who can weld joints of radiographic quality. Experienced Production and quality engineers available to comply critical customer requirements. In house NDE Level III & Level II Personnel available to comply critical NDT requirements.

— More than 25 WPS, PQR qualified with combinations like SS

to SS, CS to SS, P11 to P11, P91 to P91 etc

— Qualified ASNT Level III and Level II NDE personnel available

— Qualified welders available

— PWHT facility available

— Radiography test pit available, approved by AERB

Stainless Steel:

304 / 304L / 304H

316 / 316L / 316H

321 Carbon Steel:

SA105

SA350 LF2 (Class 1 and Class 2)

SA350 Gr. LF3 Alloy Steel:

SA182 F5

SA182 F9

SA182 F11

SA182 F22

SA182 F91 Specialty Alloys:

Duplex Stainless Steel

Super Duplex Stainless Steel

Cast Iron

Ductile Iron

Inconel

Monel

Hastelloy

On Request

Testing Methods (Destructive & Non-Destructive Testing – NDT/DT):

These are methods used to evaluate material or product properties directly, often for performance validation or defect detection.

Non-Destructive Testing (NDT):

PMI (Positive Material Identification)

Spectrometer

Liquid Penetrant Testing (LPT) / Dye Penetrant

Magnetic Particle Testing (MPT) / MPI

Ultrasonic Testing (UT) / Ultrasonic

Radiography (X-Ray Inspection) / Radiography

Hardness Testing

Dimensional Inspection

Roughness / Surface Finish

Helium Leak Test

Pneumatic Testing

Nitrogen Leak Test

Hydro Testing

Destructive Testing (DT):

Tensile Testing

Impact Testing

Microstructure Analysis

Sand Testing (when destructive for mould quality)

Quality Assurance Processes (QA):

These ensure process and product consistency, adherence to standards, and final product integrity.

Oxygen Cleaning

Shot Blasting

Painting

Powder Coating

UAE Office

India Office

UK Office

Australia Office

169-170, Badkhal Pali Road, Bhankri, Faridabad, Haryana 121004, India

+91 99589 35512

info.ind@metaval.com