The manufacturing sector is standing at the edge of a revolution, and artificial intelligence (AI) is the catalyst. By 2025, AI is projected to inject $3.7 trillion into global manufacturing, redefining how we design, produce, and deliver. At Metaval, our legacy in forging, casting, and valve manufacturing is built on precision engineering and decades of expertise. Today, we are at the forefront of a technological revolution as we integrate Artificial Intelligence (AI) into our production processes. From intelligent automation to real-time analytics, AI is redefining how manufacturers operate and scale their businesses. But what does the 2025 playbook look like for those ready to embrace AI-driven change?

Predictive Maintenance and Smart Quality Control

One of the most compelling benefits of AI in manufacturing is its ability to predict equipment failures and optimize maintenance schedules. AI-driven systems now analyze real-time sensor data to detect anomalies, which significantly reduces unexpected downtime and maintenance costs. Advanced computer vision and machine learning algorithms also ensure that quality control processes are both faster and more accurate identifying defects with up to 90% accuracy.

Metaval’s Insight:

“Integrating AI-based predictive maintenance into our production lines not only extends machinery lifespan but also guarantees superior quality control, a key factor in maintaining our competitive edge.”

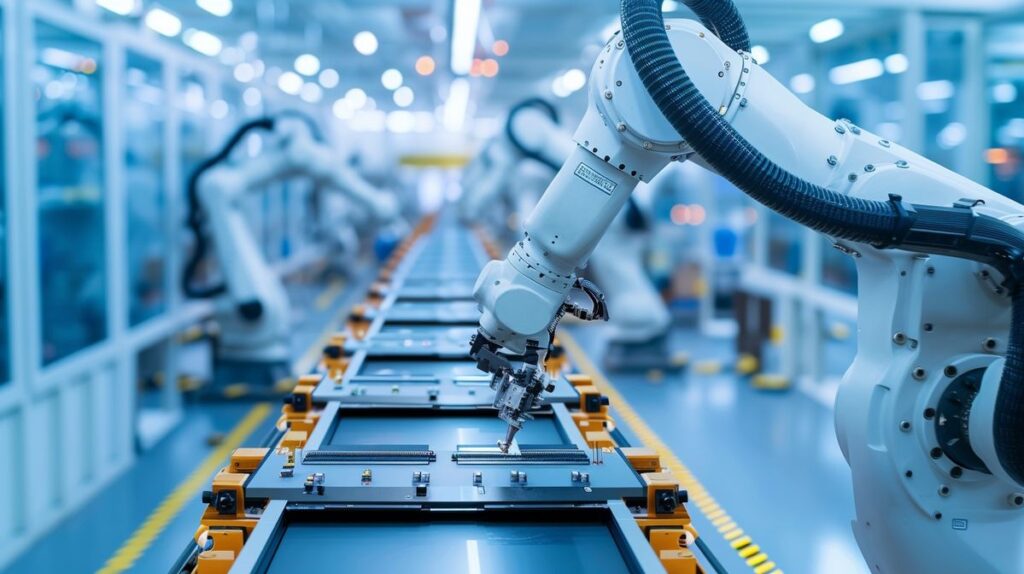

Smart Automation and Robotics

In 2025, AI is expected to push the boundaries of robotics further into smart automation. Collaborative robots (cobots) and autonomous mobile robots (AMRs) are increasingly being deployed on the factory floor. These systems can work alongside human operators—taking on repetitive, strenuous tasks while ensuring safety and efficiency. From assembling intricate components to handling logistics, the integration of AI-driven robotics is revolutionizing traditional manufacturing models.

Metaval’s Approach:

“We’re exploring partnerships to incorporate smart robotics into our production processes, ensuring that our manufacturing facilities remain agile and responsive to market demands.”

AI-Driven Supply Chain Optimization

Supply chain management is becoming increasingly complex as global market dynamics evolve. AI enables real-time data analysis, which enhances demand forecasting and inventory management. This leads to better resource allocation, reduced waste, and smoother production cycles. By leveraging AI, manufacturers can create dynamic supply chains that respond immediately to market fluctuations.

Metaval’s Perspective:

“By integrating AI-powered analytics into our supply chain, we ensure that the right materials are available at the right time, reducing lead times and streamlining production.”

Sustainability and Energy Efficiency

Sustainability is no longer optional—it’s a strategic imperative. AI is playing a crucial role in reducing energy consumption and minimizing waste. Intelligent energy management systems analyze usage patterns to optimize resource consumption, contributing to lower carbon footprints and more sustainable manufacturing practices. This not only benefits the environment but also improves overall operational efficiency and cost-effectiveness.

Metaval’s Commitment:

“Sustainability is at the heart of our production philosophy. We’re committed to integrating AI that drives energy efficiency and reduces waste, helping us meet both industry standards and environmental responsibilities.”

Embracing Human-Centric AI for Industry 5.0

Looking beyond the immediate gains, the evolution towards Industry 5.0 emphasizes a collaborative approach where AI augments human expertise. This new paradigm focuses on enhancing creativity, customization, and worker well-being. AI becomes a partner on the factory floor—automating routine tasks while enabling workers to focus on higher-value, creative endeavors.

Metaval’s Vision:

“Our goal is not just to automate but to create a harmonious human-machine collaboration that elevates our craftsmanship and innovation.”

Closing the Loop with Metaval:

As we step into 2025, we recognize that our deep-rooted commitment to quality and innovation positions us uniquely to harness these transformative AI solutions. By integrating AI-driven predictive maintenance, advanced quality control, and smart supply chain analytics into our processes, we are set to redefine the standards of efficiency and excellence. This is not merely an upgrade—it’s a reinvention of how we create, produce, and deliver our products, ensuring that every valve, forged component, and cast part meets the highest benchmarks of performance and sustainability.

Our story continues as we embrace the future, turning cutting-edge AI innovations into the tools that drive our progress and set new industry standards.