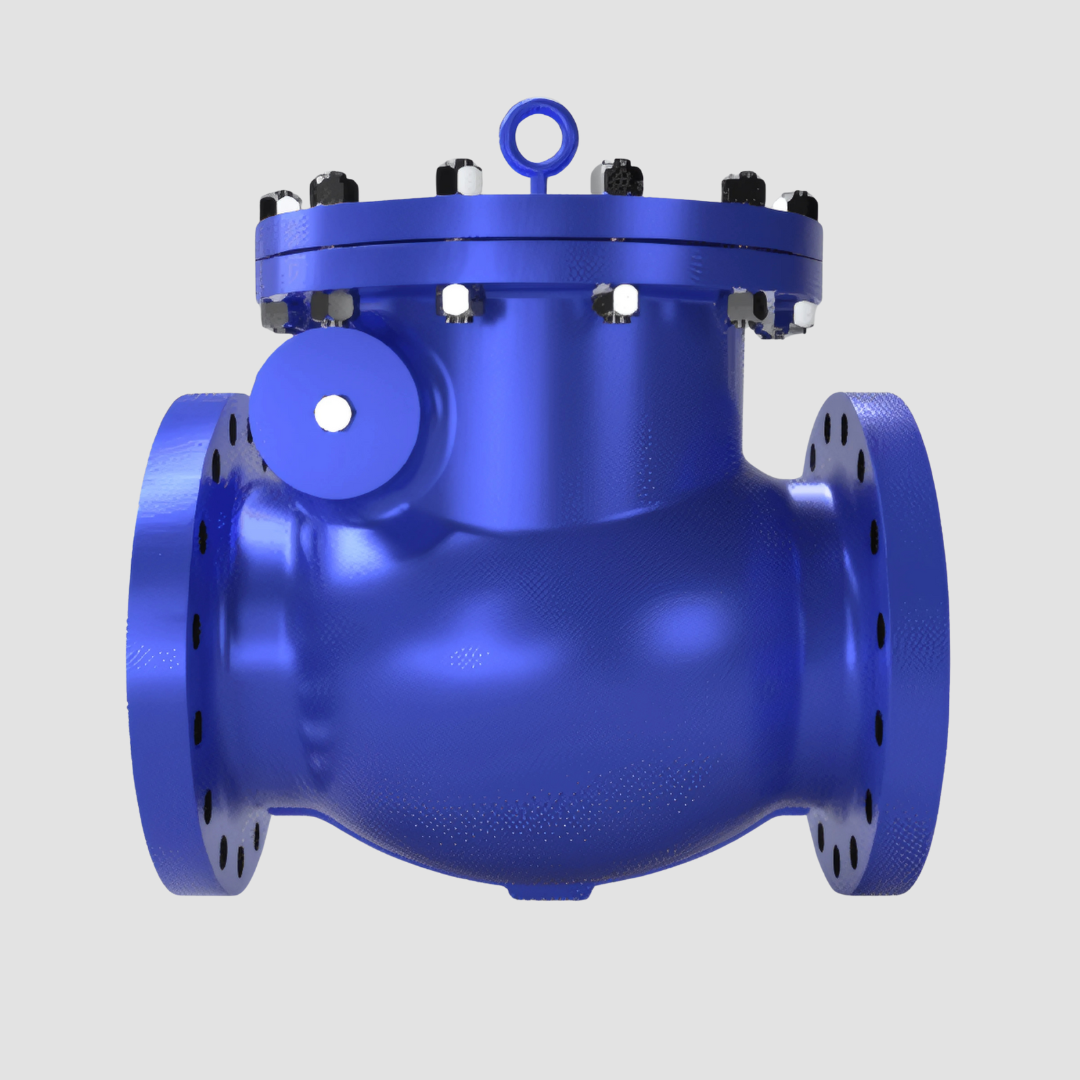

Metaval Swing Check Valves are unidirectional valves designed to prevent backflow in horizontal and vertical pipeline systems. The swing disc design ensures minimal pressure drop and is ideal for low to moderate flow velocities. These valves are reliable, easy to maintain, and widely used across process industries.

1/2” to 48”

Class 150 to 2500

PN 10 to PN 400

1/2” to 48”

Class 150 to 4500

PN 10 to PN 400

Based on body and trim material

Flanged, Butt Weld

ASME B16.10 / EN 558

Design & Manufacturing: API 6D / API 594 / BS 1868

End Connections: ASME B16.5/ B16.47 / EN 1092-1 / AS4087 / AS2129 / B16.25

Pressure-Temperature Ratings: ASME B16.34

Testing: API 598 / EN 12266-1

Body: ASTM A216 WCB, CF8, CF8M, LCB, LF2, WC6, WC9, Duplex, Inconel

Disc: WCB with hard facing, CF8 / CF8M / CA15

Gasket: Spiral Wound SS304 / SS316, Graphite, PTFE

Stud & Nut: A193 B7 / A194 2H, B8, B8M, Duplex

Low Pressure Drop: Full bore swing path

Horizontal & Vertical Mounting

Self-Operating Closure

Heavy-Duty Disc Options for Higher Pressures

Corrosion-Resistant Alloys Available

Counterweight Option for Smooth Operation

Hydrostatic, Pneumatic, Helium, Nitrogen Pressure Tests

PMI, RT, UT, MPI, DPT

Hardness, Tensile, Impact, Microstructure Testing

Surface Roughness and Spectrometer

Dimensional Inspection

Oxygen Cleaning (where required)

Water and Wastewater Systems

Oil and Gas Pipelines

HVAC Systems

Chemical and Petrochemical Plants

Power Plants

Shipbuilding and Marine Lines

Water

Air and Gases

Steam

Non-Corrosive Fluids

Slurries

CE Certified

PED 2014/68/EU

ISO 9001:2015

ISO 14001:2015

ISO 45001:2018

Fire Safe Design – API 607

Get in touch with our team for additional information on product pricing, technical data, project support and more.

169-170, Badkhal Pali Road, Bhankri, Faridabad, Haryana 121004, India

+91 99589 35512

info.ind@metaval.com