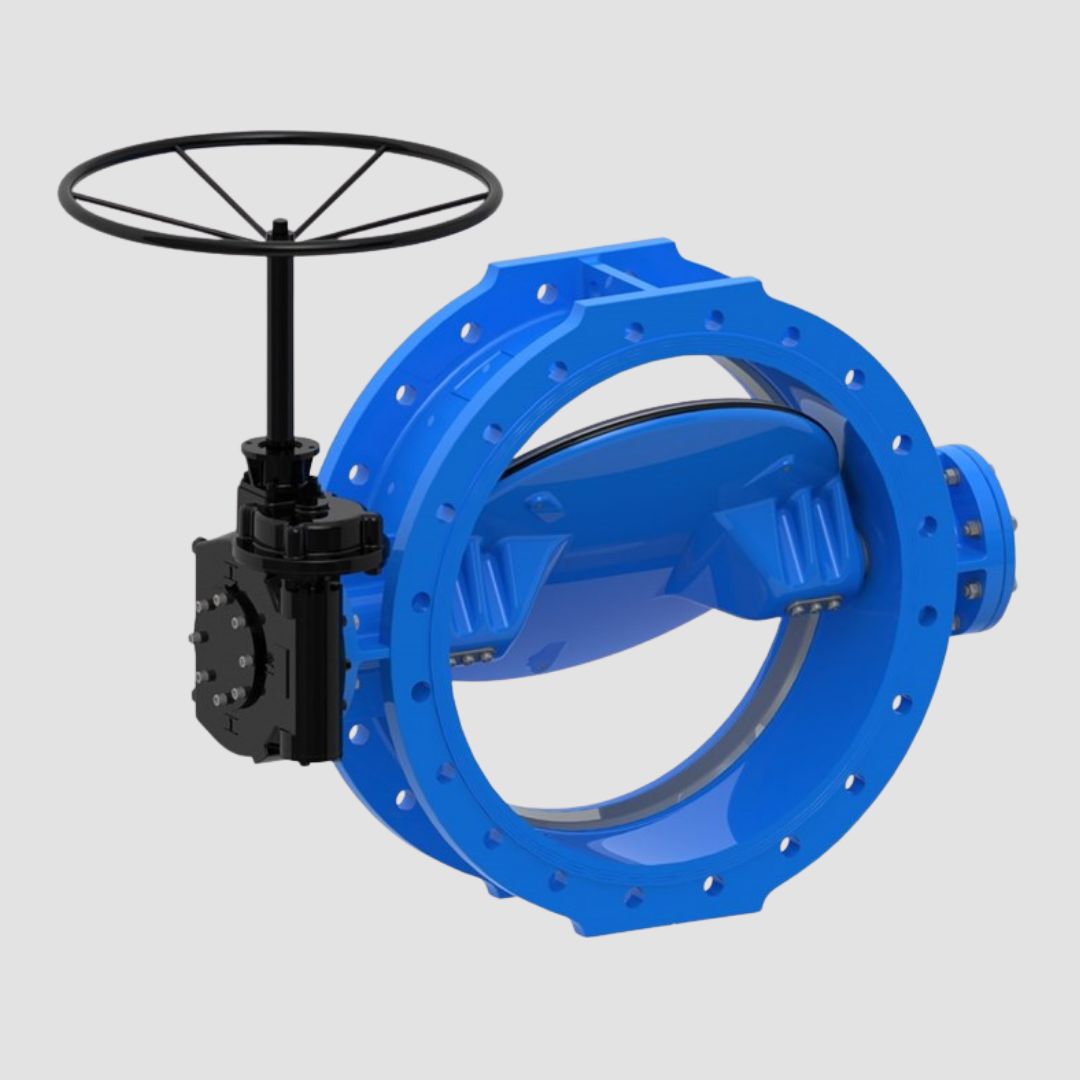

Metaval’s Eccentric (Single Offset) Butterfly Valve is a performance upgrade from the concentric design, built to reduce seat wear and improve sealing reliability. The disc shaft is offset from the valve centreline, minimizing friction between the disc and seat during opening/closing cycles. This results in extended service life and lower torque requirements, making it suitable for more demanding applications.

2” to 48”

50 to 1200

PN 10 to PN 40

2” to 48”

Class 150 / 300

DN 15 to 1200

As per trim and seat material

Wafer, Lug, Flanged

PN 10 to PN 40

Valve Design: EN 593, API 609, AWWA C504, ISO 5752

Material Standards: EN 16668

Face-to-Face: ISO 5752 / EN 558 / API 609 / ASME B16.10

Top Flange: ISO 5211

Flange Drilling: EN 1092-1, AS 4087, AS2129, ASME B16.5/B16.47, BS 5155

Testing Standards: EN 12266-1, API 598

Body: Ductile Iron, WCB, CF8, CF8M, CF3M, Duplex, Super Duplex

Disc: Stainless Steel, Duplex, Super Duplex, Monel, Inconel

Seat: Soft Seated (EPDM, NBR, PTFE, Viton)

Stem: AISI 410, F304, F316

Gasket: Spiral Wound SS / Graphite / PTFE

Reduced Friction Design: Disc disengages from seat during rotation

Low Torque Operation: Ideal for automation

Resilient Seated: Ensures tight shut-off with zero leakage

Longer Seat Life: Minimizes mechanical wear

Compact Construction: Lightweight yet rugged

All Metaval valves undergo complete QA/QC testing, including:

Hydrostatic and Pneumatic Pressure Tests

Helium / Nitrogen Seat Leak Tests

PMI and UT / RT where applicable

DPT and Surface Finish Tests

Hardness, Tensile, and Dimensional Verification

Functional Actuation Testing

Water and Wastewater Systems

HVAC and Cooling Water Systems

Chemical Processing

Mining Slurries

Utility and Firefighting Systems

General Industrial Service

Slurries and Suspended Solids

Treated and Raw Water

Mild Acids and Alkalis

Low-Pressure Steam

Gases and Vapors

CE Certified

PED (2014/68/EU)

ISO 9001:2015

ISO 14001:2015

ISO 45001:2018

Get in touch with our team for additional information on product pricing, technical data, project support and more.

169-170, Badkhal Pali Road, Bhankri, Faridabad, Haryana 121004, India

+91 99589 35512

info.ind@metaval.com