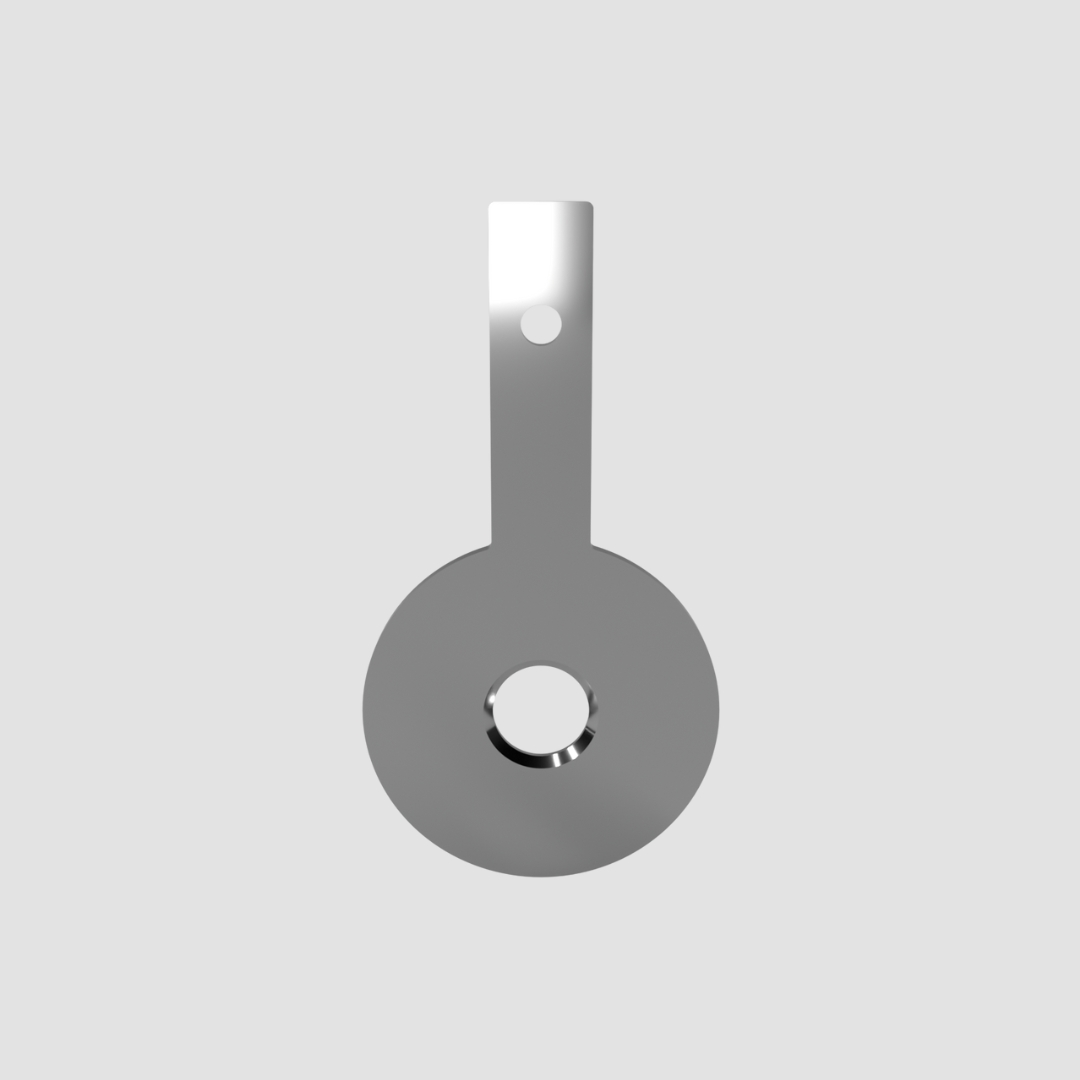

Metaval Orifice Plates are precision-engineered primary flow elements used in differential pressure flow measurement systems. Designed to meet international standards, these plates provide reliable, repeatable, and economical solutions for a wide range of process conditions.

From 1/2" (15 NB) up to 24" and above

ANSI 150# to 2500#

As per requirement

0.1 to 0.75 depending on type

≤ 0.5% of flow rate

Quadrant & Conical types: Best suited for low Reynolds number flows.

Segmental & Eccentric: Designed for slurry or dirty service.

Multi-hole: Reduces noise, cavitation, and vibration.

±0.5% to ±2% of full-scale flow rate

Required for non-symmetrical types (e.g., Eccentric, Segmental)

Design Standards: ISO/TR 15377, ISO 5167, RW Miller, ASME MFC-3M, ASME 19.5, AGA-3, L K Spink

Size Range: From 1/2″ (15 NB) up to 24″ and above

Plate Thickness: 3 mm / 6 mm / 10 mm / 12 mm / As per requirement

Orifice Plate Material: SS304, SS316, Duplex 2205, Super Duplex 2507, Monel 400, and custom alloys

Flange Material: Carbon Steel, LTCS, Stainless Steel, Alloy Steel, Monel 400

Pressure Rating: ANSI 150# to 2500#

Mounting Options: Wafer type or flanged assemblies

Flow measurement of liquids, gases, and steam

Custody transfer and fiscal metering

Chemical and petrochemical industries

Power generation and utilities

Oil & gas transmission pipelines

Water treatment and desalination plants

ISO 9001:2015 Quality Management

ISO 14001:2015 Environmental Management

ISO 45001:2018 Occupational Health & Safety

PED 2014/68/EU – Pressure Equipment Directive

ILAC-MRA & NABL ISO 17025 Certified Calibration (on request)

Get in touch with our team for additional information on product pricing, technical data, project support and more.

169-170, Badkhal Pali Road, Bhankri, Faridabad, Haryana 121004, India

+91 99589 35512

info.ind@metaval.com