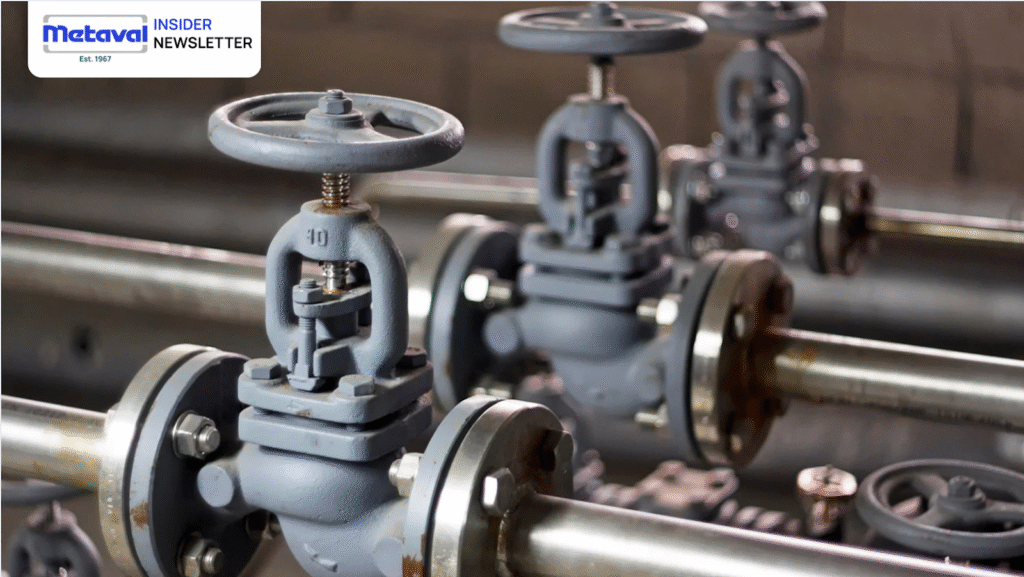

In the intricate symphony of modern industrial operations, valves are often the unsung heroes, meticulously controlling the flow of critical fluids. As manufacturing landscapes rapidly evolve, driven by demands for increased efficiency, sustainability, and precision, so too must the technology of these vital components. At Metaval, we are not just witnessing this transformation; we are actively shaping it through innovation in materials, automation, and smart valve technologies.

The global industrial valve market, valued at approximately USD 95.57 billion in 2024, is projected to grow significantly, reaching an estimated USD 152.33 billion by 2034, exhibiting a Compound Annual Growth Rate (CAGR) of 4.8% from 2025-2034. This robust growth underscores a fundamental shift in how industries perceive and utilize valve technology

Advanced Materials: Engineered for Tomorrow’s Demands

The performance envelope for industrial valves is constantly expanding, requiring materials that can withstand increasingly harsh conditions from extreme temperatures and pressures to highly corrosive or abrasive media. Metaval recognizes that the right material is the bedrock of valve reliability and longevity.

- Next-Gen Alloys and Composites: Beyond traditional steel, we’re seeing a rise in advanced alloys and specialized composites. These materials offer superior resistance to corrosion, erosion, and wear, significantly extending valve lifespan and reducing maintenance needs. For instance, the use of duplex stainless steel and Inconel alloys is becoming more prevalent in aggressive environments.

- Ceramic Linings and Specialized Coatings: For abrasive applications, ceramic linings provide exceptional wear resistance. Additionally, advanced coatings like thermal barrier coatings (TBCs) and diamond-like carbon (DLC) enhance durability, reduce friction, and improve heat dissipation.

- Eco-Friendly Materials: As sustainability gains traction, the focus is also shifting towards materials with a lower environmental footprint, including considerations for recyclability and reduced energy consumption during production.

These material advancements enable valves to perform reliably in demanding sectors like oil & gas, chemical processing, and power generation, minimizing downtime and enhancing safety.

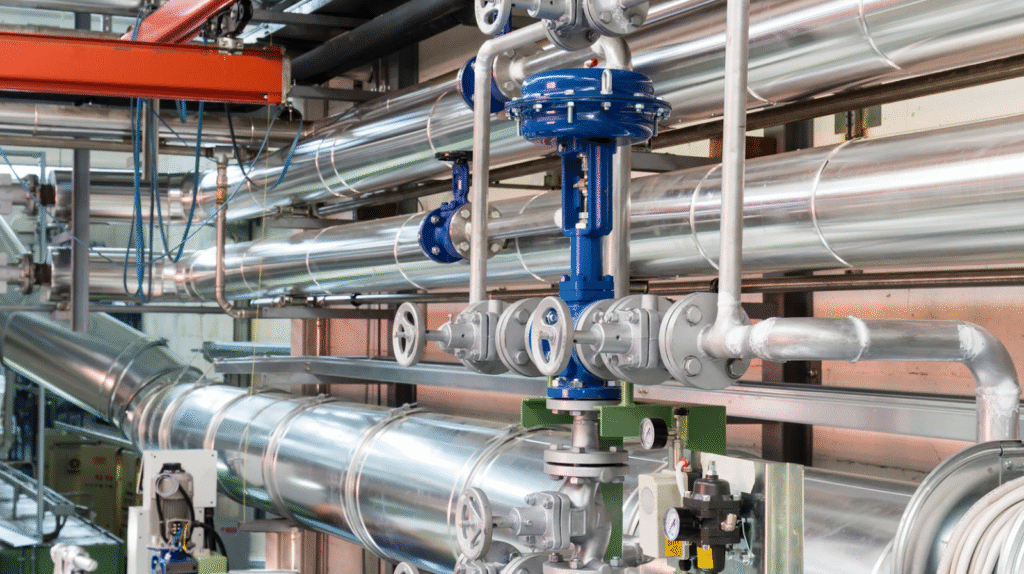

Automation: Precision, Efficiency, and Safety Redefined

The integration of automation in valve operations is fundamentally transforming manufacturing processes, moving beyond simple on/off control to sophisticated, real-time adjustments.

- Intelligent Actuators: Electric, pneumatic, and hydraulic actuators are becoming more intelligent. They offer precise control and can be integrated seamlessly with Programmable Logic Controllers (PLCs), Distributed Control Systems (DCS), and Supervisory Control and Data Acquisition (SCADA) systems, enabling centralized control and optimized process management.

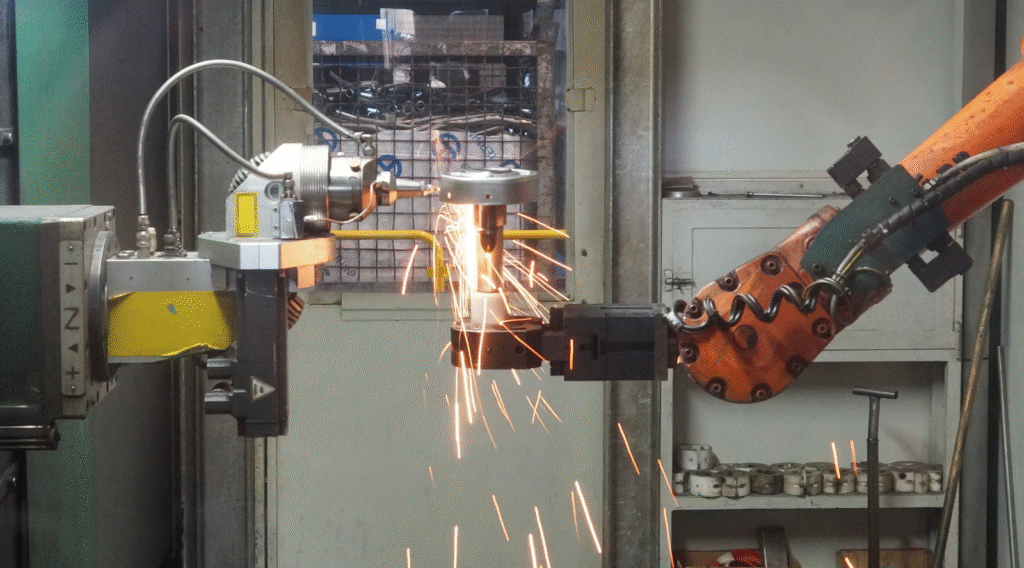

- Robotics in Manufacturing: In valve production itself, advanced robotic systems are being deployed for tasks such as precise machining, assembly, and rigorous quality control. This leads to enhanced productivity, consistency, and a significant reduction in human error.

- AI and Machine Learning: Artificial intelligence and machine learning are increasingly pivotal in automating industrial valves in demanding environments. Their predictive capabilities can forecast maintenance needs and optimize performance, reducing downtime and extending valve life.

This push towards automation ensures not only higher operational efficiency but also significantly improves safety by reducing human exposure to hazardous environments.

Smart Valves: The Era of Intelligence and Connectivity

Perhaps the most transformative trend is the advent of smart valves, which are at the heart of the Industrial Internet of Things (IIoT) revolution.

- Real-time Monitoring and Data Analytics: Smart valves are equipped with integrated sensors and communication capabilities that provide real-time data on performance metrics such as temperature, pressure, flow rates, and vibration. This data is crucial for informed decision-making and process optimization.

- Predictive Maintenance: By analyzing continuous data streams, AI-powered algorithms can predict potential issues before they lead to system failures. This enables proactive maintenance scheduling, significantly reducing unexpected downtime and operational costs.

- Remote Control and Optimization: IIoT-enabled valves can be controlled remotely, allowing operators to adjust settings from centralized locations, enhancing responsiveness and adapting to changing conditions automatically. Digital twins—virtual replicas of physical valves—further enhance planning, simulation, and performance optimization.

- Enhanced Safety and Compliance: Smart features like self-diagnosing capabilities and real-time alerts enhance safety by quickly identifying anomalies and ensuring compliance with stringent industry regulations.

Metaval’s Commitment to the Future

At Metaval, we are deeply invested in these technological advancements. Our commitment to research and development, coupled with strategic collaborations with leading material scientists and automation experts, ensures that our valves are not just components, but intelligent solutions driving the next generation of industrial efficiency and sustainability.

By embracing smart technologies, innovating with advanced materials, and leveraging cutting-edge automation, we empower our clients to achieve unprecedented levels of operational excellence, safety, and environmental responsibility.

How are these trends impacting your operations? Share your insights in the comments below!